LETU Engineering students have access to labs and equipment from day one.

Over the years, LETU has invested millions of dollars in

- Mechanical

- Civil and Environmental

- Electrical and Computer

- Materials Joining

- Biomedical

- Engineering Graphics

- MakerLab

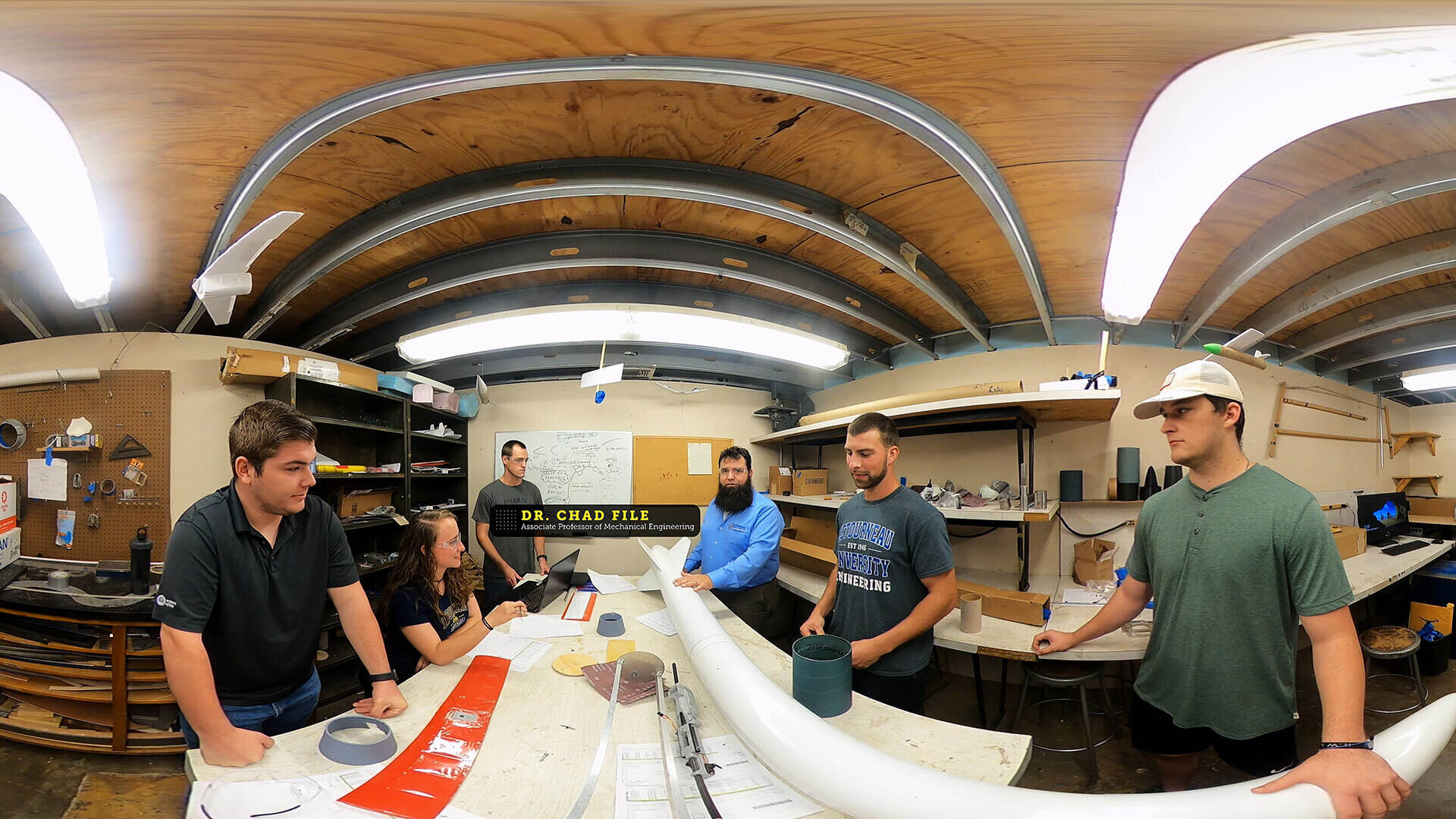

Mechanical Engineering Labs

Mechanical Engineering Labs 1 & 2

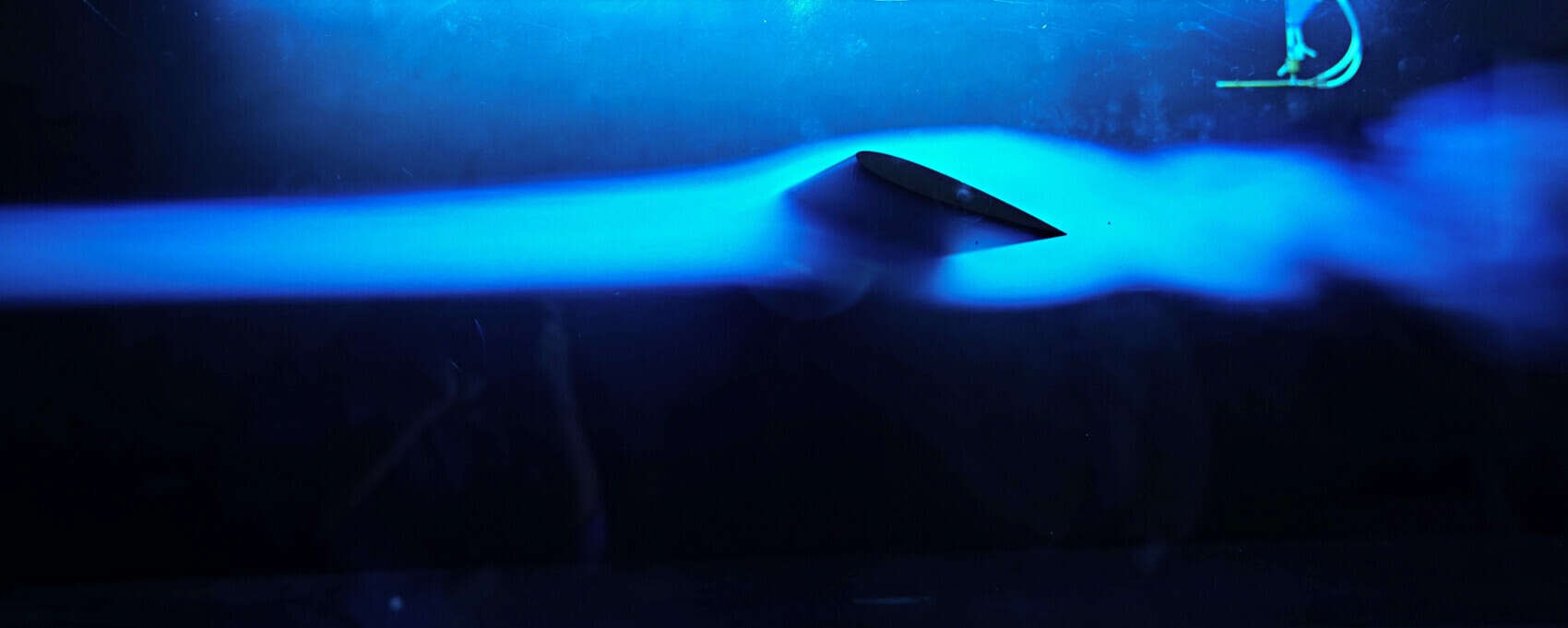

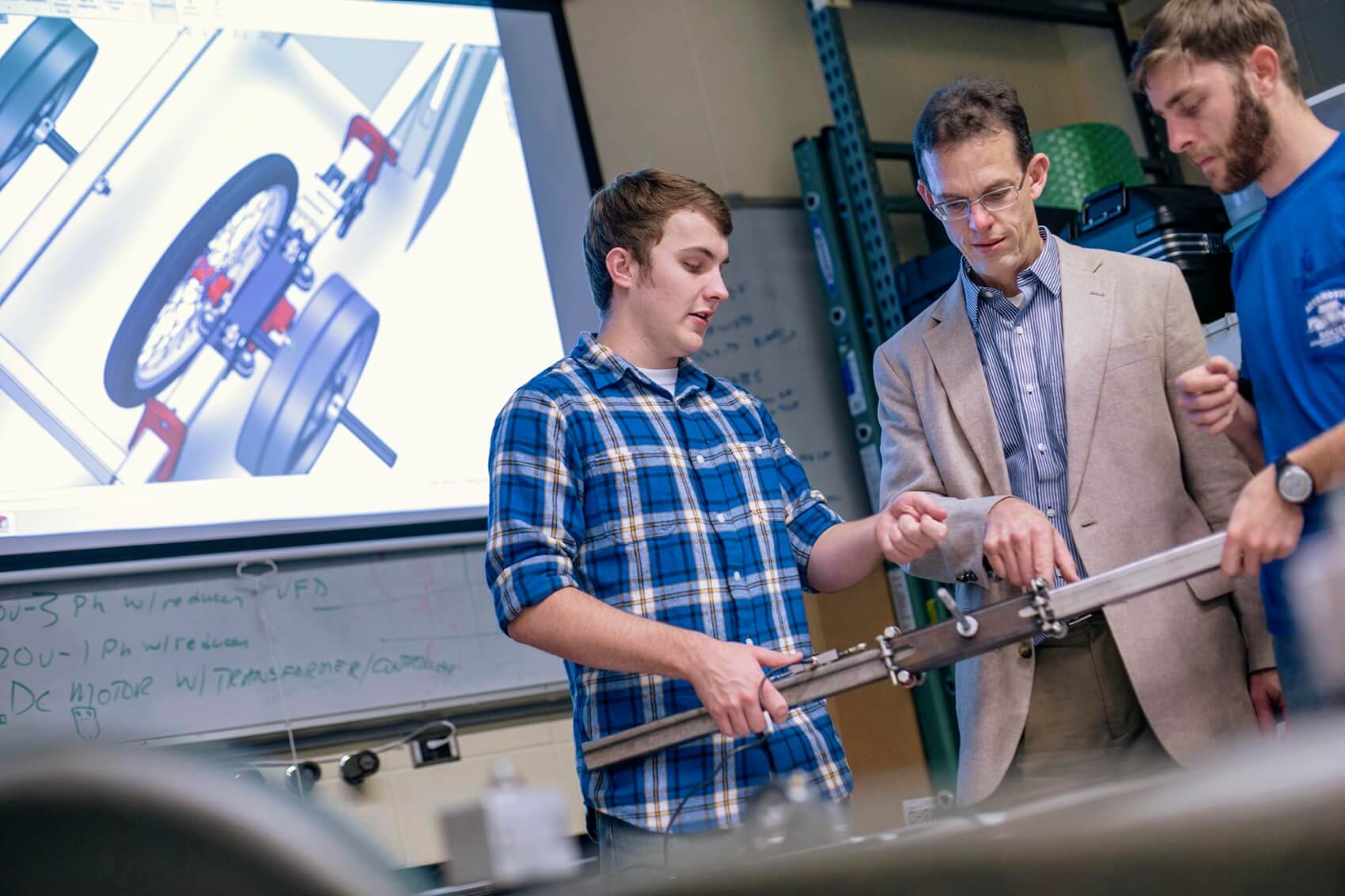

Students use a variety of apparatuses to conduct experiments that allow them to explore physical phenomenon of Mechanical Engineering courses and use transducers to collect data with modern data acquisition systems for analysis. This lab is where theory, application, differential equations and hands on skills combine to display the beauty and consistency of physical phenomenon. Example experiment topics include temperature measurement, convection coefficient determination, spring damper response, spring mass response, heat transfer, and flow experiments. A student favorite is the wind tunnel, which is capable of class 3 hurricane speeds of 111 miles/hour during aerodynamic testing of an adjustable angle airfoil. Students can measure air speed and airfoil lift as well as visualizing air flow using fog injected into the air stream.

Machine Tool & Design Lab

The Machine Tool and Design Lab is a 7,300 sq. ft.

The Glaske Center for Engineering, Science & Technology

The Glaske Center houses approximately 3800 sq. ft. of labs utilized by ME

Facilities include lab space for the following:

- Mechanics and Measurements

- Thermal and Fluid

science - Vibrations

- Mechatronics

- Electronics and Circuits

Composites Lab

The Composites Lab includes a clean-room fabrication area for conventional laminated composites using glass and carbon fiber. It also contains a large paint-booth which has been modified for the fabrication of

Learn about our degrees in:

Civil and Environmental Engineering Labs

Hands-on, active learning experiences is the central element to civil engineering education at LeTourneau University. The department maintains several different civil engineering labs to facilitate this type of work and to provide students with the best possible learning environment. These facilities and equipment are used by civil engineering students from freshman through senior year.

Civil Materials Lab

The Civil Materials Lab contains a wide range of equipment for characterizing and testing steel, concrete, wood, plastic

Structural Testing Pad

The Structural Testing Pad is an outdoor facility for testing larger structural components and systems. Class and project work in the Structural Testing Pad involves using reaction frames that can withstand loads up to 100,000 lb in bending to test concrete beams and bridge deck sections, a 35-ft steel beam and connection tester, a lateral testing frame for housing structures and wall panels, and a 100,000 lb axial load frame for columns and wall sections.

Teaching Lab

The Teaching Lab is a seminar-style classroom with cutting edge educational technology that can be used both for class lectures and student collaborations.

Environmental Lab

The Environmental Lab contains testing equipment and facilities that allow students to perform basic water quality analysis, hydraulic system modeling, and the construction and testing of water treatment reactors. Junior and senior level students are able to work with a spectrophotometer, water quality sensors, chemistry materials, and other environmental engineering equipment.

Water Lab

The Water Lab is a new lab setup, and includes a pipe network for hydraulic analysis, a viscometer, an open channel flume, a constant head water supply, and other pieces of equipment for hydraulic and hydrological experimentation.

Geotechnical Lab

The Geotechnical Lab contains materials and equipment allowing students to conduct soil characterization and testing exercises. This lab also houses basic asphalt manufacturing, conditioning, and testing equipment.

Projects Lab

The Projects Lab is a big, open creative space allowing students to construct larger class projects indoors. A large stock of steel, wood, and pipe components is available for student structural and hydraulic build projects, along with the relevant manufacturing and construction equipment.

Senior Design Lab

The Senior Design Lab is a new 2000+ square foot lab space dedicated to up to three annual civil engineering senior design projects. Senior students have open access to a shared working space, basic tools and well-stocked hardware, study area, and meeting room to facilitate a unique, two-semester capstone senior design experience.

Learn about our degrees in:

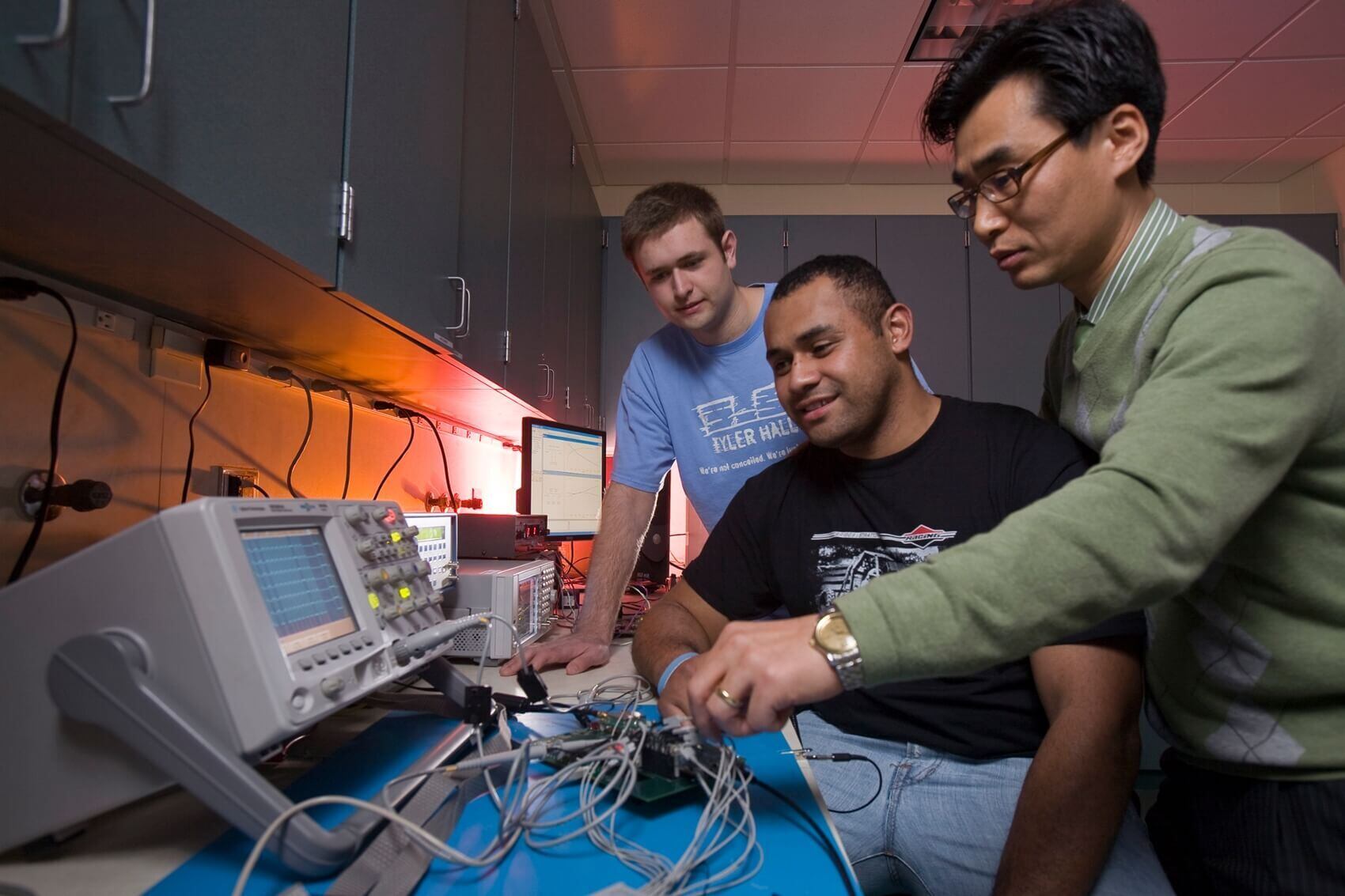

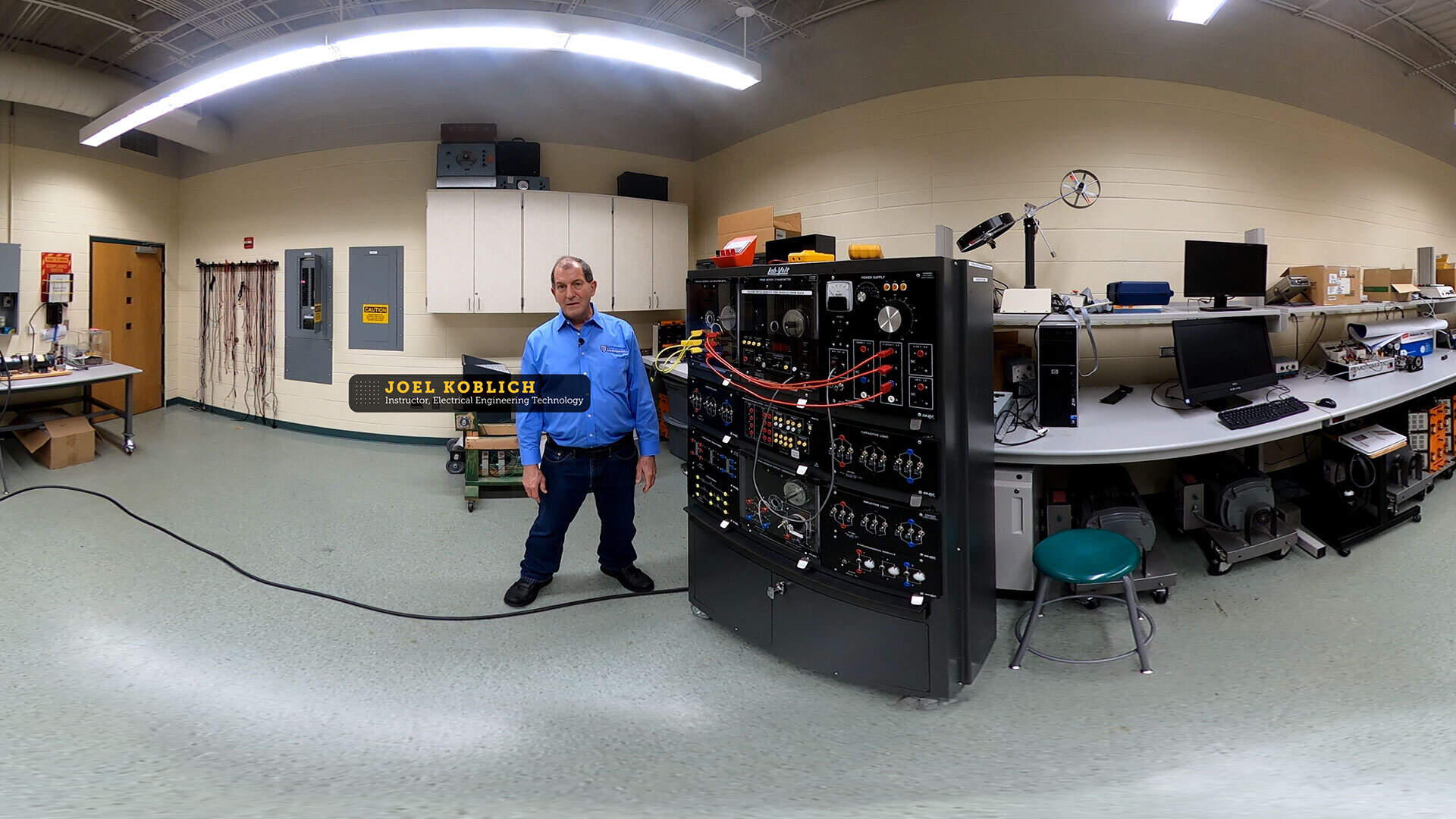

Electrical and Computer Engineering Labs

The Electrical and Computer Engineering facilities include lab space for teaching, research, and senior design projects.

- Introduction to Engineering Practices Lab Introduction to Engineering Practice is a two-semester course that allows our freshmen students to learn early what it is that engineers actually do. In the first semester, our students build an intricate machine, such as a plotter. In the second semester, students learn about the engineering design process, teamwork development, ethics, professionalism, and reporting. Below is a video of some of the fun they have in this class.

- LETU 3D Printer Workshop

- Advanced Communications Lab The Advanced Communications lab supports courses in communications and digital signal processing. The lab has been used primarily for senior design projects.

- Advanced Electronics Lab Students use this lab for circuits and electronics lab assignments, and to work on projects involving electronic circuits.

- Communications Lab The Communications lab supports courses in communications and digital signal processing. The lab has been used primarily for senior design projects.

- Electronics Lab In this

- Mechatronics Lab The Mechatronics lab houses equipment for the study of electrical motors and generators. It is used primarily by engineering technology students taking the Electrical Machinery course.

- Microcomputer Design Lab The Microcomputer Design Lab supports a course in which students design, build and test a single-board computer. It has also been used for senior design projects.

- Microprocessor/Microcontroller Lab The Microprocessor / Microcontroller lab is equipped with microcontroller and microprocessor trainers and with programmable logic controllers (PLCs). It is primarily used by engineering and engineering technology students who take microcontroller or microprocessor classes. This is also where engineering technology students learn to use programmable logic controllers.

- Robotics Lab Here is where students taking the Robotics course learn how to program industrial robots. The lab is equipped with one delta robot and four articulated robots, including two collaborative robots.

Learn about our degrees in:

Materials Joining Engineering Labs

For 45 years, William "Bill" Kielhorn diligently educated welding engineering and welding engineering technology students at LeTourneau University. Despite being hospitalized for stage IV colon cancer during his last semester, Kielhorn never missed a class in his entire 45-year career. His last lecture was given via Skype from his hospital bed.

Just days later, LeTourneau University commemorated his life and career by naming the university's welding lab the Kielhorn Welding Engineering Lab in his honor. Kielhorn was released from the hospital for a few hours, allowing him to attend the dedication ceremony. Eight months later, Mr. Kielhorn's battle with cancer took him to be with the Lord.

Most of the Materials Joining Engineering facilities are housed in the 8600-square-foot Kielhorn Welding Engineering Laboratory, the largest stand-alone Materials Joining Lab in the nation. The lab contains over a million dollars worth of equipment, virtually all of which is available to students for class projects and research experiments.

The lab contains equipment to facilitate any number of different welding and joining processes, including multiple types of arc welding, spot welding, friction stir welding, brazing, soldering, adhesive bonding, hybrid joining and more.

The lab also contains equipment that enables automation and control, weldability testing, characterization, mechanical testing, nondestructive evaluation

See the Partial Equipment List

Learn about our degrees in:

Biomedical Engineering Labs

The Biomedical Engineering laboratories are located within the Glaske Center for Engineering, Science and Technology. These labs are equipped with state of the art research and design equipment. LETU students use the biomedical engineering facilities to complete projects for individual courses, as well as for research conducted for senior design projects.

- Motion Analysis System

The Motion Analysis system allows students to conduct motion capture, building a three-dimensional model of test subjects in movement for analysis. The motion analysis equipment, valued at more than $200,000, was purchased through an NSF grant written by LETU faculty members. LeTourneau is one of the few undergraduate programs in the nation to have such a system.

- BioSignal Studies

In addition to the motion analysis equipment mentioned above, the NSF grant was also used to purchase equipment for studies in bioinstrumentation to obtain computerized measurements of cardiovascular, respiratory, and neurological functions. Signals such as the EEG, EKG (ECG) and EMG are then processed to maximize information content.

- Electromyography (EMG) System

The BME laboratory is equipped with a wireless EMG system measuring the electrical signals outputted by multiple muscles when activated. - Six Degree of Freedom Force Plate

The pit in the BME laboratory contains 20 individual tiles that are removable. Two six-axis force plates are installed into the pits to accurately measure multi-dimensional ground reaction forces. These forces result from such actions as a person walking over the force plate or jumping on it. The data from the force plates are combined with the kinematic data from the motion capture system and the EMG system to provide comprehensive analyses of human movement.

Learn about our degrees in:

Engineering Graphics Lab

Located in the Glaske Center for Engineering, Science

- All classrooms have

multimedia equipment. - A state-of-the-art auditorium is available for special lectures and events.

- 24 seat computer station Computer Aided Design (CAD) classroom/lab. Each station is loaded with state-of-the-art CAD software.

Laser cutting, 3D printing, routing, waterjet cutting, and t-shirt making are all available in the state-of-the-art MakerLab. This well-equipped workspace also displays six generations of LETU 3D printers built by each freshman in previous years. Most importantly, the next generation of engineers build their stories here. We are grateful to the Solheim Foundation for their generous support.

See the MakerLab in Action starting at 8m:40s.