What is Welding Engineering?

Some would answer this question with imagery of welders in masks peering down at an arc as they lay down a bead on a seam. While that is indeed one type of welding process, there is much more to the world of welding engineering, and LeTourneau University can prepare you for all of it.

Welding engineering encompasses many different processes, including:

- Various methods of welding

- Brazing

- Soldering

- Adhesive bonding

- Certain kinds of mechanical fastening.

Advances in the technology of these processes enable a wide variety of materials, such as metals, ceramics, polymers, composites and electronic materials, to be joined in ways that maximize reliability and minimize cost.

Welding engineers invent new, safer and more efficient processes, create engineering specifications, and contribute to the performance and integrity of everything from consumer products to space vehicles.

LeTourneau University has a rich history of training welding experts and is one of only three universities in the nation that provides an ABET-accredited engineering program with a welding or materials joining concentration.

INTERESTING CLASSES YOU'LL TAKE

- Mechanics of Materials

- Materials Science of Joining

- Joining Procession and Power Systems

- Materials Testing & Characterization Lab

To learn more about course requirements

- view program details in our current catalog

- see our most recent suggested course sequence

- view the list of approved electives for this degree

PROJECT HIGHLIGHTS

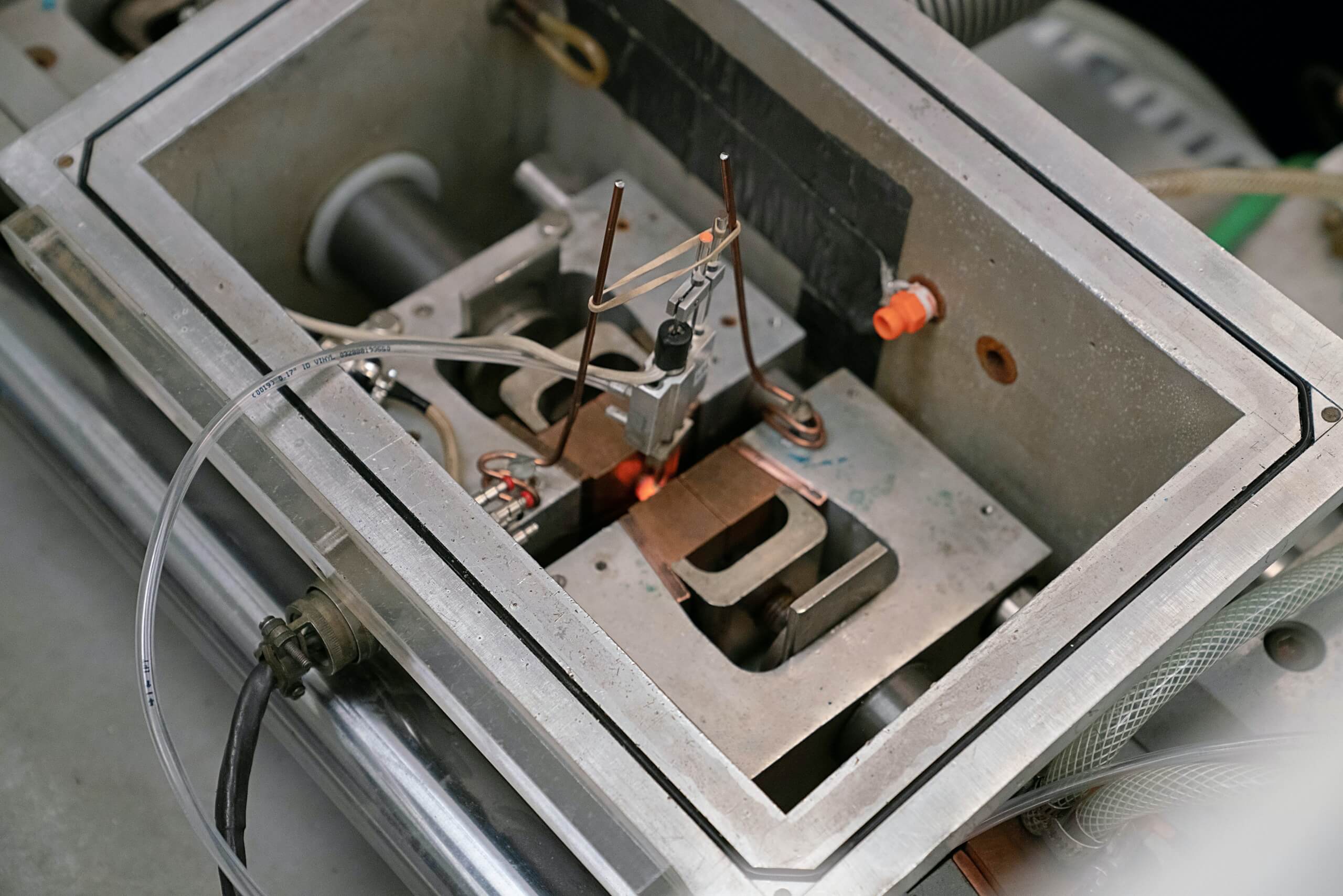

FSW (Friction Stir Welding) is a solid state process which uses a rotating tool to 'mix' the solid metal together, creating a metallurgical bond.

The U.S. Transportation Dept. is looking for an effective way to join High Performance Steel (HPS) 70 and A1010 stainless steel with FSW, and LETU students are developing ways to improve the process.

The Additive Manufacturing Fusion Processes Senior Design Team is working to model, make, and test a functionally gradient transition piece for joining chromoly steel to nickel-based alloys. The transition piece is needed due to different coefficients of thermal expansion and the thermal loading that joints can experience in certain applications. Successful completion of the project will lay the groundwork for other currently difficult joints between dissimilar metals.

WHAT CAN YOU DO WITH A WELDING ENGINEERING DEGREE?

Engineers who understand the engineering aspects of joining materials and the science of metallurgy are sought after for essential work in infrastructure, and also by companies that produce:

- Aircraft carriers

- Skyscrapers

- Fighter jets

- Pressure vessels

- Piping systems

- Machinery used for various manufacturers