Through Failures and Disappointments

After dropping out of school at the age of 14, R.G. was exposed to metallurgy and molding for the first time while working for foundries in Portland, Oregon and San Francisco, California.

As a result of the Great San Francisco Earthquake of 1906, Robert moved to Oregon where he pulled tree stumps for his brother. It was here that Robert tried his hand at modifying a machine to do the job more efficiently. The invention backfired, quite literally, knocking out Roberts front teeth. Back in San Francisco, R.G. found work refurbishing batteries for the Yerba Buena Power System, where he also learned to weld with an oxyhydrogen welding torch. This became a defining characteristic of his career - his preference for welding in manufacturing.

At the age of 21, he enrolled in a handful of correspondence courses and conferred on himself a “Bachelor of Motorcycles”, with the hopes of becoming an auto mechanic. Eventually, R.G. was hired by a garage in Stockton, California and later, at the age of 23, became co-owner of the newly opened Superior Garage. It was in 1912, at the San Joaquin County Fair, that R.G. broke his neck when riding as a passenger in a car he had modified for the race. His neck leaned to the right for the rest of his life.

Robert returned to Superior Garage in 1918, after volunteering at Mare Island Navy Yard during the First World War, to find the company he had left in his partners hands on the edge of bankruptcy. To pay off the debt, R.G. took a job repairing a broken tractor for a farmer. Not convinced that R.G. had fixed the tractor, Robert proceeded to level 40-acres of land with the repaired tractor and a borrowed scraper to prove his work. This success led to invitations to fix other machines as well, though this temporary work was short-lived.

Moving Earth

By 1920, at the age of 32, Robert found himself out of work yet again. With a recommitted Christian faith and a discovered love for machines, he combined his past experience with metallurgy, welding, and more to meet the needs of the bustling local farming community. He purchased a 1915 Holt tractor, offered repair work in exchange for borrowing a friend’s scraper, mortgaged what little they owned for a $1,000 loan, and took his first job at a nearby ranch.

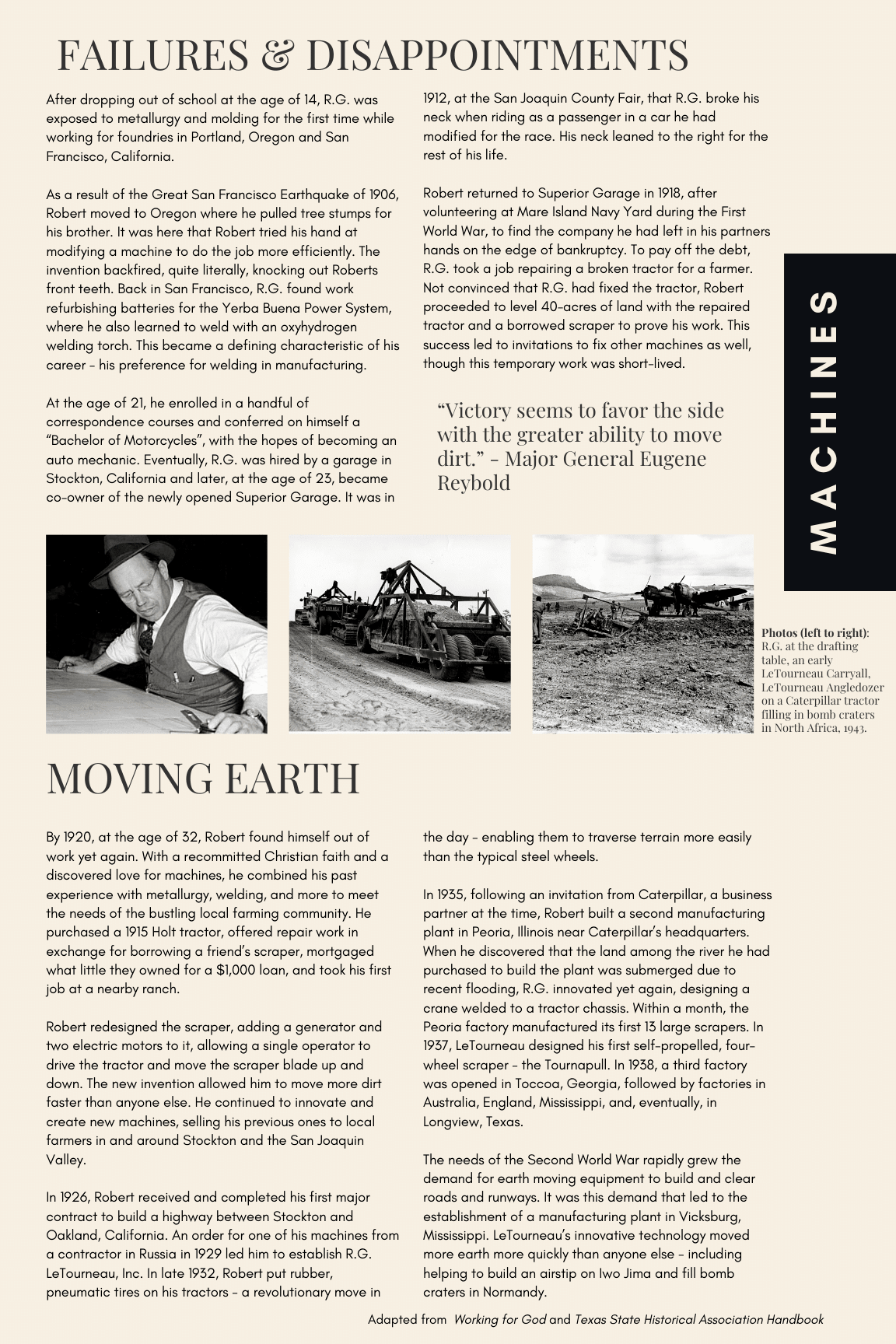

Robert redesigned the scraper, adding a generator and two electric motors to it, allowing a single operator to drive the tractor and move the scraper blade up and down. The new invention allowed him to move more dirt faster than anyone else. He continued to innovate and create new machines, selling his previous ones to local farmers in and around Stockton and the San Joaquin Valley.

In 1926, Robert received and completed his first major contract to build a highway between Stockton and Oakland, California. An order for one of his machines from a contractor in Russia in 1929 led him to establish R.G. LeTourneau, Inc. In late 1932, Robert put rubber, pneumatic tires on his tractors - a revolutionary move in the day - enabling them to traverse terrain more easily than the typical steel wheels.

In 1935, following an invitation from Caterpillar, a business partner at the time, Robert built a second manufacturing plant in Peoria, Illinois near Caterpillar’s headquarters. When he discovered that the land among the river he had purchased to build the plant was submerged due to recent flooding, R.G. innovated yet again, designing a crane welded to a tractor chassis. Within a month, the Peoria factory manufactured its first 13 large scrapers. In 1937, LeTourneau designed his first self-propelled, four-wheel scraper - the Tournapull. In 1938, a third factory was opened in Toccoa, Georgia, followed by factories in Australia, England, Mississippi, and, eventually, in Longview, Texas.

“Victory seems to favor the side with the greater ability to move dirt.” - Major General Eugene Reybold

The needs of the Second World War rapidly grew the demand for earth moving equipment to build and clear roads and runways. It was this demand that led to the establishment of a manufacturing plant in Vicksburg, Mississippi. LeTourneau’s innovative technology moved more earth more quickly than anyone else - including helping to build an airstrip on Iwo Jima and fill bomb craters in Normandy.

(Adapted from Peel, Working for God and Texas Historical Association Handbook.)